Find Double Layer Roll Forming Machines, Double Layer Forming Machines, Double Layer Cold Forming Machine on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Model No.: Double Layer-IBR and Glazed

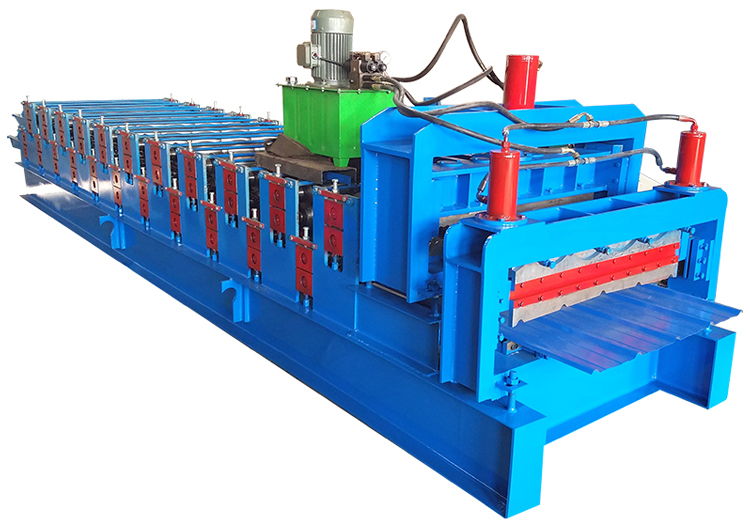

The Double layer roll forming machine can produce two different profile drawings on one machine, saving more room and more money when compared with using two different machines. The double layer Roll Forming Machine can produce one layer profile at a time. There is one clutch on the side of the machine and we just need to move one handle wheel to roll form the other layer profile.

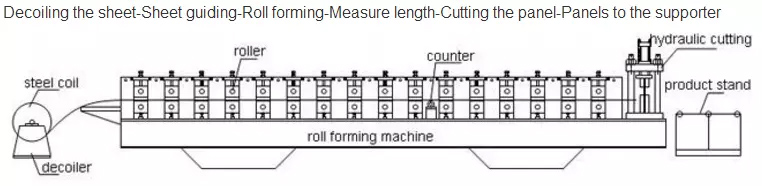

Roll Forming Machine Parameters :

Double Deck Roof Sheet Cold Roll Forming Machine Material Specification colored steel sheet Input width 1250mm Effective width 1000mm Roller station 11rows Coil Thickness 0.3-0.8mm Forming speed 8-12m/min Main motor power 4kw Hydraulic power 4kw Roller material high grade No.45 forged steel, with 0.05mm plated coating Shaft material 45# high grade steel,diameter 75mm PLC Delta brand Custom According to customer's requirements

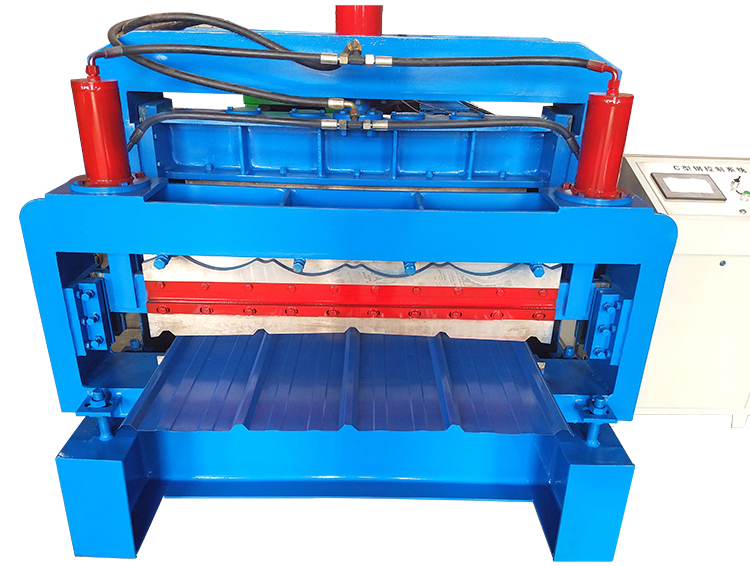

Roll Forming Machine Display :

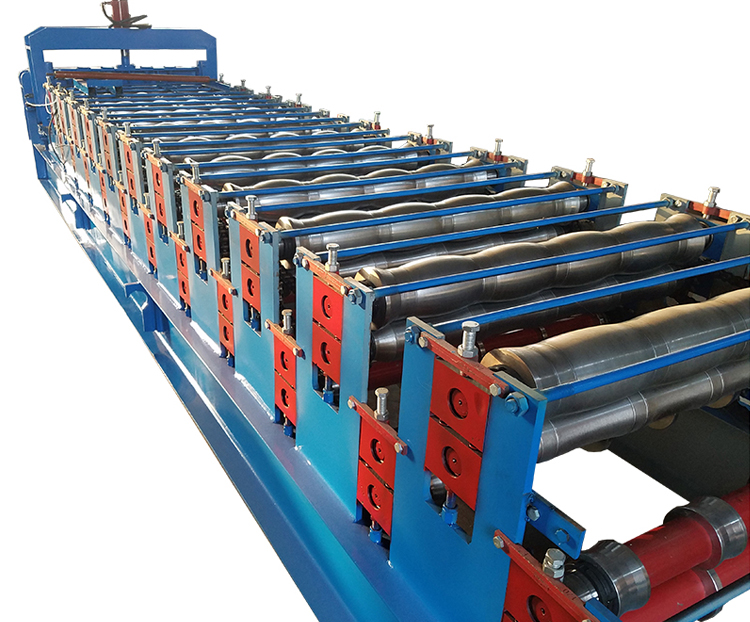

Roller System

1. Material: high grade NO.45 forged steel.

2. Roller station: 11-16(depends on final design)

3. Thickness of feeding material:0.3-0.8mm

Automatic Control System

1. Screen: touch screen or text screen

2. Automatic length measurement

3. Automatic quantity measurement

4. Computer is used to control length and quantity. Machine will automatically cut to length and stop when required quantity is achieved.

5. Length inaccuracy can be amended easily.

Usage: It is used to support the steel coil and uncoil it in a turnable way.

Loading capacity :5T

Inner diameter:450-508mm

Company Profile

Botou Hongyuan Forming Machine Co.,Ltd has been established in 2005 as a professional manufacturers of roof Tile Roll Forming Machine. We use AUTO CAD design software. With more then 10 years of experiences and strict quality control, our roof sheet roll forming machines meet International Standard. We are the leading manufacturer and reported of roll forming machine in China. We manufacture various kinds of roof tile roll forming machine for producing the following products.Our Roll Forming Machine contain Glazed Roof Tile Roll Forming Machine,Trapezoidal Roll Forming Machine ,Corrugated Roll Forming Machine , Double Layers Roll Forming Machine ,C Z Purlin Roll Forming Machine , Steel Structure Floor Deck Forming Machine etc.

Packaging Details:

1. one 40ft container for loading one set machine with manual decoiler;

2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

Product Categories : Roof Tile Roll Forming Machine > Double Layers Roll Forming Machine