Model NO.: DX 850 Forging Forming Method: Mold Forging Feature: Automation Warranty: 24 Months Advantage: Use Widely Name: 850 Corrugated Iron Sheet Making Machine/Galvaniz Material Thickness: 0.3-0.8mm Feeding Width: 1000mm Pump Power: 4 Kw Shaft Diameter: 75mm Trademark: DIXIN Origin: Botou Hebei China Type:

Rolling Machine Power Source: Hydraulic Pressure Certification: CCC, SGS, ISO9001, CE Customized: Customized Condition: New Processing Material: Galvanized Steel/Colored Steel Coil Effective Width: 850mm Main Motor Power: 4 Kw Speed: 8-12m/Min Forming Steps: 13 Steps Specification: CE ISO BV HS Code: 845522 Corrugated iron roofing sheet roll forming making

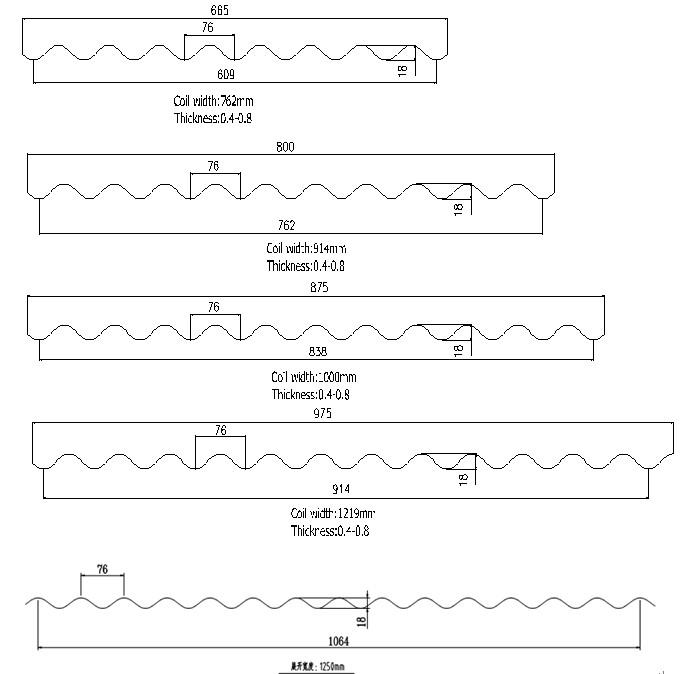

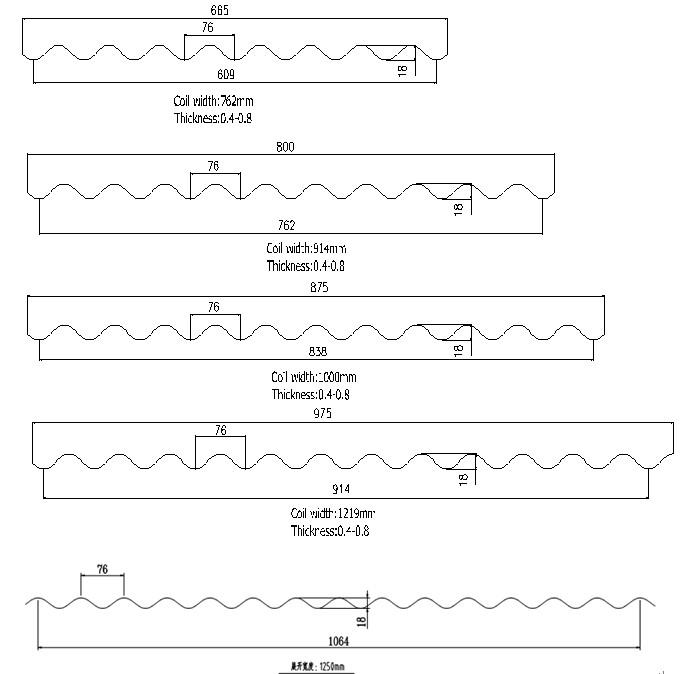

2. Technique parameters

(1) Processing material: galvanized steel/colored steel coil

(2) Material thickness: 0.3-0.8mm

(3) Effective width: 850mm

(4) Feeding width: 1000mm

(5) Main motor power: 4 kw

(6) Pump power: 4 kw

(7) Speed: 8-12m/min

(8) Shaft diameter: 75mm

(9) Forming steps: 13 steps

(10) Roller material: 45# forged steel, with hard chrome plating

(11) Main frame: 300H steel

(12) Medium plate thickness: 14mm

(13) Control systerm: PLC computer control with inverter

(14) Power supply: 380V, 3 Phase, 50Hz

(15) 0veral sized: 6500mm*1500mm*1200mm

Equipment Components

Decoiler 1Unit

Feeding Guide 1 Unit

Roll Forming System: 1 Unit

Press&Cutting Device 1 Unit

Hydraulic Station 1 Unit

PLC control System 1 Unit

Runout Table 2Units

| 1 | Coil width | 1000mm |

| 2 | Cover width | 850mm |

| 3 | Coil sheet thickness | 0.2-0.8mm |

| 4 | Material of frame | 300H steel |

| 5 | Diameter of shaft (solid shaft) | (high grade) 45# Steel |

| 6 | Diameter of shaft (solid shaft) | 75mm |

| 7 | Treatment of roller | quenched and tempered treatment, hard chromized coated 0.05-0.07mm |

| 8 | Thickness of middle plate | 14mm |

| 9 | Forming station | 13 stations |

| 10 | Drive type of Roll Forming Machine | drive by chain(0.8 inch) |

| 11 | Power of main motor | 4KW |

| 12 | Motor power of hydraulic station | 4KW |

| 13 | Oil pump of hydraulic station | No.46 gear oil pump (high grade) |

| 14 | Forming speed | about 8-12 m/min |

| 15 | Voltage | 380V/50Hz/3phase |

| 16 | Hydraulic cutting | cutting controlled by PLC |

| 17 | Accuracy of cutting | +/- 1mm |

| 18 | Razor blades material | Cr12, quenching 58-62 ° |

| 19 | Electrically controlled system | entire machine controlled by PLC |

| 20 | PLC | DELTA(TAIWAN) |

| 21 | Weight of main Forming Machine | About 3 T |

3.Payment term: 30%TT in advance,70% before the shipment.

4.Warranty: 12 month, and lifelong technician support.

Contact us if you need more details on Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about

Roof Roll Forming Machine、

Tile Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Roof &Wall Roll Forming Machine