Find Sandwich Vacuum Packing Machine, Cnc Cold Roll Forming Machine, Cold Roof Sandwich Panel Maing Machine Line on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Payment Type: | L/C,T/T |

|---|---|

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 45 Days |

Model No.: EPS /Mineral wool sandwich panel line

Producting sketch:

Producting sketch:

Manual decoiler

Manual decoiler

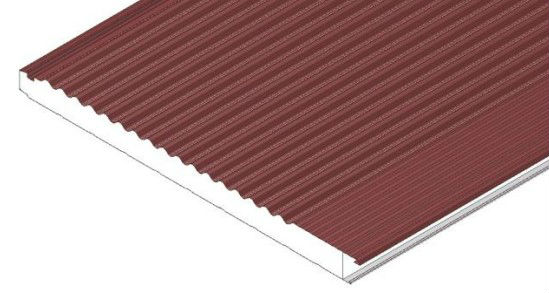

Panel Line Staging COIL HOLDERS– Options for coil handling range from basic mandrel type systems to fully cantilevered driven coil holders with coil cars. JOINT ROLL FORMING– The Full Spec Line roll forming system is forming joints for wall, secret fix and roof profiles in a compact side transfer unit. This full line roll-forming system is superior due to extra forming length and all forming being done prior to any core introduction. Also available are very economical systems in the Modular and Classic ranges as well as the heavy duty “Euroline”. CORE LOADING– Options include a variety of cores such as EPS and Mineral Wool which is loading from stacks of sheets or prepared lamellas. The special features include complete flexible setup ability with unique core in-feed systems. FAMWOLF– Incorporates a fully automatic Mineral Wool handling and preparation system for cutting, turning and feeding Mineral Wool without the need for pre-cutting of Mineral Wool into lamellas. CORE SANDING– we have a range of core preparation systems which include diamond coated roller-sanding, planing and linishing. CORE TRIMMING– Systems include TCT cutting as well as the new Multi Type cutting systems for ultimate in speed and flexibility. The system utilises several cutting heads to ensure optimal cutting finishing especially on Mineral Wool and composite cored panel systems. GLUE APPLICATION– we offer a variety of solutions including wiping and spraying systems. The standalone glue system allows interchanging the system to suit the needs of every production line. This system can even be made interchangeable with an injection system for PUR and PIR foams. LAMINATING PRESS– Various length Roller Presses are available for different line speed requirements or Caterpillar Presses for ultimate laminating experience. The Caterpillar System can also be configured or retrofitted to allow the production of injected foamed panels on a Laminating System. PANEL CUTTING– A range of panel cutting systems including the proven Universal Bandsaw. Cutting Systems can include overlap rebate saws for roof panels as well as several other options and combinations. CONVEYORS– Several options are available for run out conveyors to take panels from the saw to further processing including free rolling, motorised systems as well as reject tipping conveyors. PANEL STACKING– The Panel Stacking Systems can be fitted with the latest designed Panel Flipper and Conveyor Systems as required. The Panel Stacking System can be configured in various lengths and types including options such as positioning systems, in-feed and exit conveyors, board and pallet loading systems for below the stack to exit conveyor types, etc. PANEL PACKAGE CONVEYORS– After stacking, panels are transported to other processing EXTRACTION SYSTEM – we offer several types of extraction systems to suite each production line including standard bag houses to full reverse pulse-jet systems as required for the correct Mineral Wool dust extraction. PANEL WRAPPING– The Spiral Wrapper is an Automatic Wrapper which wraps the pack in stretch film. The machine as standard includes automatic film cut off and starting, internal driven conveyor to assist in wrapping shorter packs and gear set pre-stretching of the film. Various options include items such as automatic EPS leg loading under panel stacks and automatic end film wrapping. Other Options Other options – available are: overlap removal system, overlap film insertion system, automatic leg insertion under panel packs, core cutting with automatic coldwire or hotwire, reject panel transfer conveyors, board loading and laminating systems, GFK/GRP laminating systems, side tape application, protective foil application. return to top our standard profiles of sandwich panel.

Panel Line Staging COIL HOLDERS– Options for coil handling range from basic mandrel type systems to fully cantilevered driven coil holders with coil cars. JOINT ROLL FORMING– The Full Spec Line roll forming system is forming joints for wall, secret fix and roof profiles in a compact side transfer unit. This full line roll-forming system is superior due to extra forming length and all forming being done prior to any core introduction. Also available are very economical systems in the Modular and Classic ranges as well as the heavy duty “Euroline”. CORE LOADING– Options include a variety of cores such as EPS and Mineral Wool which is loading from stacks of sheets or prepared lamellas. The special features include complete flexible setup ability with unique core in-feed systems. FAMWOLF– Incorporates a fully automatic Mineral Wool handling and preparation system for cutting, turning and feeding Mineral Wool without the need for pre-cutting of Mineral Wool into lamellas. CORE SANDING– we have a range of core preparation systems which include diamond coated roller-sanding, planing and linishing. CORE TRIMMING– Systems include TCT cutting as well as the new Multi Type cutting systems for ultimate in speed and flexibility. The system utilises several cutting heads to ensure optimal cutting finishing especially on Mineral Wool and composite cored panel systems. GLUE APPLICATION– we offer a variety of solutions including wiping and spraying systems. The standalone glue system allows interchanging the system to suit the needs of every production line. This system can even be made interchangeable with an injection system for PUR and PIR foams. LAMINATING PRESS– Various length Roller Presses are available for different line speed requirements or Caterpillar Presses for ultimate laminating experience. The Caterpillar System can also be configured or retrofitted to allow the production of injected foamed panels on a Laminating System. PANEL CUTTING– A range of panel cutting systems including the proven Universal Bandsaw. Cutting Systems can include overlap rebate saws for roof panels as well as several other options and combinations. CONVEYORS– Several options are available for run out conveyors to take panels from the saw to further processing including free rolling, motorised systems as well as reject tipping conveyors. PANEL STACKING– The Panel Stacking Systems can be fitted with the latest designed Panel Flipper and Conveyor Systems as required. The Panel Stacking System can be configured in various lengths and types including options such as positioning systems, in-feed and exit conveyors, board and pallet loading systems for below the stack to exit conveyor types, etc. PANEL PACKAGE CONVEYORS– After stacking, panels are transported to other processing EXTRACTION SYSTEM – we offer several types of extraction systems to suite each production line including standard bag houses to full reverse pulse-jet systems as required for the correct Mineral Wool dust extraction. PANEL WRAPPING– The Spiral Wrapper is an Automatic Wrapper which wraps the pack in stretch film. The machine as standard includes automatic film cut off and starting, internal driven conveyor to assist in wrapping shorter packs and gear set pre-stretching of the film. Various options include items such as automatic EPS leg loading under panel stacks and automatic end film wrapping. Other Options Other options – available are: overlap removal system, overlap film insertion system, automatic leg insertion under panel packs, core cutting with automatic coldwire or hotwire, reject panel transfer conveyors, board loading and laminating systems, GFK/GRP laminating systems, side tape application, protective foil application. return to top our standard profiles of sandwich panel.

Sale Mannger : Morre yin Botou FaDa Numerical Control Goffer Tile MachineCo.,LTD Fuzhuang Development Area of Botou City 104 Road,Hebei Province,China,062150 Mobile: +86 13091161261 URL:http://xinfada.en.alibaba.com http://steelpipes.org/hbfadacom/ru/ " Save Paper, Save Earth, Print only if you Must! " Contact us if you need more details on Eps Heat Preservation Board Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Eps Sandwich Machine、Mineral Wool Insulation Board Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Sale Mannger : Morre yin Botou FaDa Numerical Control Goffer Tile MachineCo.,LTD Fuzhuang Development Area of Botou City 104 Road,Hebei Province,China,062150 Mobile: +86 13091161261 URL:http://xinfada.en.alibaba.com http://steelpipes.org/hbfadacom/ru/ " Save Paper, Save Earth, Print only if you Must! " Contact us if you need more details on Eps Heat Preservation Board Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Eps Sandwich Machine、Mineral Wool Insulation Board Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : ESandwich Panel Forming Machine